Choosing the right desktop CNC machine can significantly impact your projects, whether you’re a hobbyist, an artist, or a small business owner. This guide will walk you through critical considerations to help you make an informed decision. We’ll cover everything from understanding your needs to comparing features and budgeting. By the end of this article, you’ll have a clear roadmap for picking the best desktop CNC machine for your workshop.

Understanding Your Needs

Define Your Goals

The first step in choosing the right desktop CNC machine is understanding what you intend to do with it. Are you looking to produce intricate art pieces, or do you need a machine for more rigorous engineering projects? Different tools are designed for different purposes, so it’s essential to know your end goal.

For example, if you plan to work with softer materials like wood or plastic, a less powerful machine may suffice. Conversely, if you plan to cut metals, you’ll need a more robust model with higher torque capabilities.

Determine the Material

The type of material you will be working with can also influence your choice. Not all CNC machines are designed to handle the same range of materials. Some machines are specialized for softer materials such as wood and plastic, while others can manage hard metals like aluminum or steel.

Make sure to check the specifications of any machine you’re considering to ensure it can handle the materials you plan to use. Misjudging this can result in poor performance, or worse, damage to the machine.

Key Features to Consider

Spindle Power

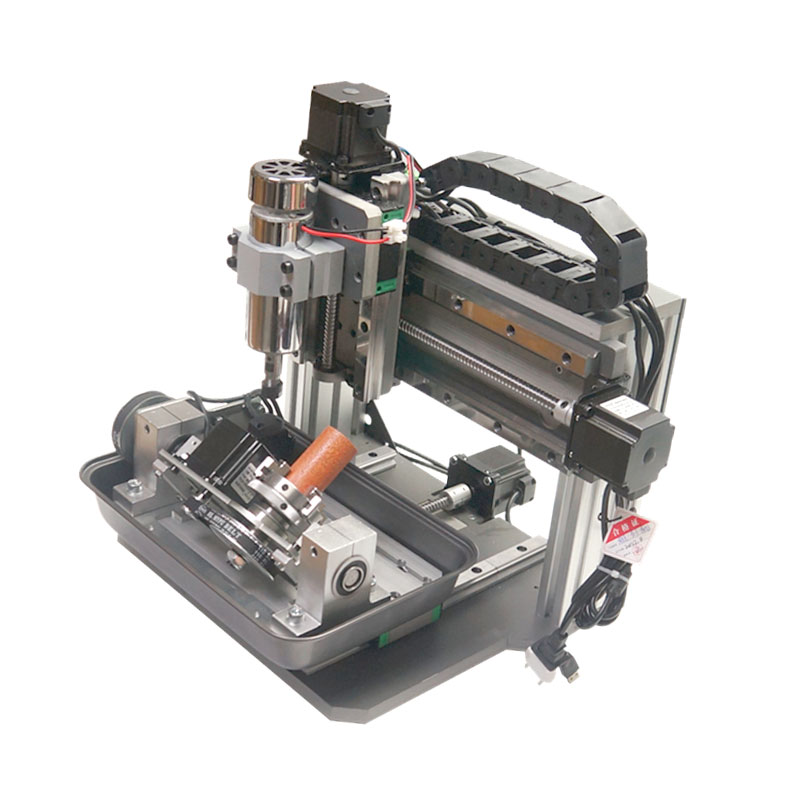

One of the most critical components of a desktop CNC machine is its spindle. The spindle is responsible for producing the rotational force that cuts or carves the material. Generally, the higher the spindle power, the more versatile the machine.

For those who need to cut or carve tough materials, look for a machine with a spindle power of at least 1.5kW. Hobbyists working with easier materials might find that 0.5-1kW is sufficient for their needs.

Working Area

The working area defines the maximum size of the material you can fit into the machine. If your projects involve large pieces, you’ll need a machine with a spacious working area. Conversely, if you plan to make intricate, small-scale items, a large working area may be unnecessary and could even become a hindrance.

Be realistic about the typical size of the pieces you’ll be working on and choose a machine where you’ll have enough space to work comfortably.

Software Compatibility

User-Friendly Interface

Software is a critical component of the CNC experience. Even the most advanced machine will be challenging to use if the control software is complex or counterintuitive. Look for software that is user-friendly and matches your level of technical expertise. Some machines come with proprietary software, while others are compatible with a range of third-party programs.

For beginners, software that offers a guided experience or has a strong community for support can be invaluable. Experienced users may prioritize software that offers advanced features and customization options.

File Format Support

Compatibility with various file formats is another important factor. Ensure that the CNC machine’s software can import and work with the file types you commonly use. For instance, if you’re a designer who uses CAD software, make sure the CNC software can import files in formats like DXF or STL.

Manufacturers usually provide a list of compatible file formats. Take the time to review this list before making your final decision.

Budget Considerations

Initial Investment

Desktop CNC machines come in a wide range of prices, from a few hundred to several thousand dollars. Establish a budget upfront to narrow down your choices. Remember that a higher price often translates to better features and durability, but this isn’t always the case.

Consider what features are non-negotiable for you and which ones you can compromise on. For beginners, it might be wise to start with a less expensive model to see if CNC machining is something you’ll stick with long-term.

Maintenance and Upgrades

Beyond the initial cost, consider the long-term expenses associated with the CNC machine. Replacement parts, software updates, and routine maintenance can add up. Some machines require proprietary parts that can be more expensive, while others use generic parts that are cheaper and easier to find.

Take the time to research the availability and cost of spare parts for the machine models you’re considering. A less expensive machine can become costly if its parts are rare or expensive to replace.

Vendor Customer Support

Warranty and Support

Customer support can make or break your experience with a desktop CNC machine. Machines are complex devices that can encounter various issues. A solid warranty and responsive customer support can save you a lot of headaches.

Check reviews and testimonials to get a sense of the company’s customer service reputation. Look for vendors that offer comprehensive warranties and have an established track record of supporting their products.

Training and Resources

Finally, consider the availability of training and educational resources. Many vendors offer tutorials, manuals, and even in-person training sessions. These resources can be particularly useful for beginners or those looking to expand their skills.

Some companies provide online communities where users can share tips, troubleshoot issues, and showcase their projects. These communities can be an invaluable source of support and inspiration.

Maintenance and Durability

Regular Maintenance

Like any piece of equipment, desktop CNC machines require regular maintenance to ensure longevity and peak performance. When choosing a machine, consider how easy it is to maintain. Some machines come with self-lubricating parts or tool paths that are easy to access for cleaning.

Look for machines with clear, straightforward maintenance instructions and readily available replacement parts. Machines that are complicated to maintain can result in prolonged downtime and increased frustration. Regular maintenance will not only extend the life of your machine but also help you avoid costly repairs.

Build Quality

The build quality of a CNC machine is a significant indicator of its durability and precision. Machines with solid frames, often made from materials such as cast iron or aluminum, are generally more stable and produce more accurate cuts. Pay attention to details like the quality of the linear guides and bearings.

If possible, opt for machines from reputable manufacturers known for high-quality construction. It might be tempting to go for a cheaper model, but investing in a well-built machine can save you from long-term issues and frequent replacements.

Power Supply and Electrical Requirements

Voltage Compatibility

Before purchasing a desktop CNC machine, check its voltage requirements and ensure that it is compatible with your local power supply. Some machines may require a step-down transformer or a dedicated power outlet to function correctly.

Running a CNC machine on an incompatible power supply can cause significant damage to both the machine and your electrical system. Therefore, it’s crucial to verify these details and, if necessary, consult with an electrician to ensure a safe setup.

Energy Consumption

Consider the energy consumption of the CNC machine, especially if you plan to run it frequently or for extended periods. Machines with higher spindle power typically consume more electricity, which can be a consideration if you’re mindful of energy costs.

Look for machines with energy-efficient features or those that allow you to tweak settings to reduce consumption without compromising performance. Energy consumption is an often-overlooked factor that can have a significant impact on your operating costs over time.

Mobility and Space Requirements

Physical Size

The physical size of the CNC machine is an important consideration, especially if you have limited workspace. Measure your available space and compare it to the machine’s dimensions, including any additional space needed for movement and operation.

Some machines come with optional stands or mounting kits that can help you optimize space usage. Ensure there’s ample room not just for the machine itself but also for material storage and the safe movement of parts.

Portability

If you need to move your CNC machine between different locations, consider its portability. Some desktop CNC machines are designed to be lightweight and portable, making them easier to transport.

Portability can be a valuable feature for those who work in shared spaces, educational settings, or attend trade shows and demonstrations. Check the weight and dimensions of the machine and look for features like carrying handles or detachable components that make it easier to move.

Choosing the right desktop CNC machine requires careful consideration of various factors, from understanding your specific needs to evaluating features, software compatibility, and budget. By taking a structured approach, you can make an informed decision that aligns with your goals and requirements. Remember, the best machine for you is one that fits your unique needs and helps you accomplish your objectives efficiently. So take your time, do your research, and you’ll find the perfect desktop CNC machine to elevate your projects to the next level.